Industry Knowledge

Understanding Absorbency in Gauze Rolls and Bandages to Improve Wound Care Outcomes

Absorbency is one of the most critical factors in determining the effectiveness of gauze rolls and gauze bandages in clinical and home care environments. While the basic idea behind absorbency is simple—soaking up wound exudate—its technical underpinnings are far more nuanced. The actual performance of gauze depends on several factors: fiber material, ply count, weave tightness, and even the method of sterilization. Each of these contributes to how much fluid a dressing can hold, how quickly it can absorb, and how well it maintains a clean environment to promote healing.

At the core of absorbent capacity is the type of material used. Traditional cotton gauze is known for its natural hydrophilic properties, making it a reliable choice for many types of wounds. However, as medical demands evolve, non-woven and synthetic alternatives have entered the market, often designed to outperform standard cotton in specific areas like fluid retention and reduced linting. In high-drainage wounds, a loosely woven cotton gauze may simply not suffice, which is why understanding the absorbency levels of various gauze rolls becomes essential for both medical professionals and procurement managers.

Another key variable is the ply and layering of gauze bandages. A higher ply count generally means a thicker and more absorbent product, but that’s not always synonymous with better performance. The balance lies in ensuring adequate absorbency without creating excessive bulk that can hinder mobility or increase pressure on sensitive areas. This is where professional-grade gauze rolls show their value, offering multi-ply construction that balances absorption and flexibility without compromising comfort.

Weave pattern also plays a role, especially in rolled gauze. A tighter weave tends to limit the gauze’s ability to absorb fluid quickly, though it may be preferred in cases where slow saturation is desired to prevent maceration. Conversely, an open weave allows for rapid fluid uptake but may require more frequent changing. This trade-off means that gauze bandages should be selected based on both the wound’s characteristics and the intended application—surgical dressing, trauma response, or long-term care.

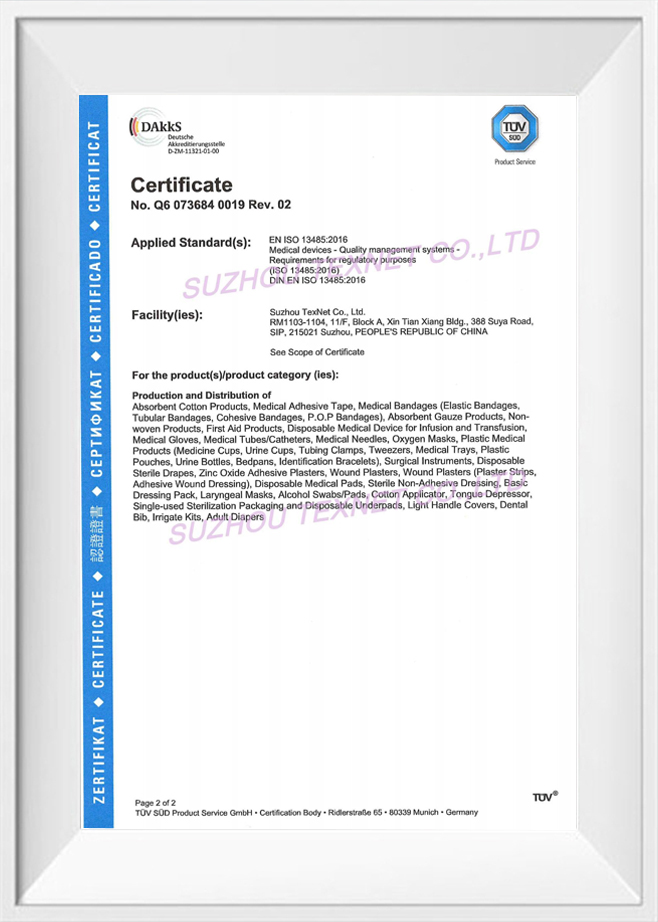

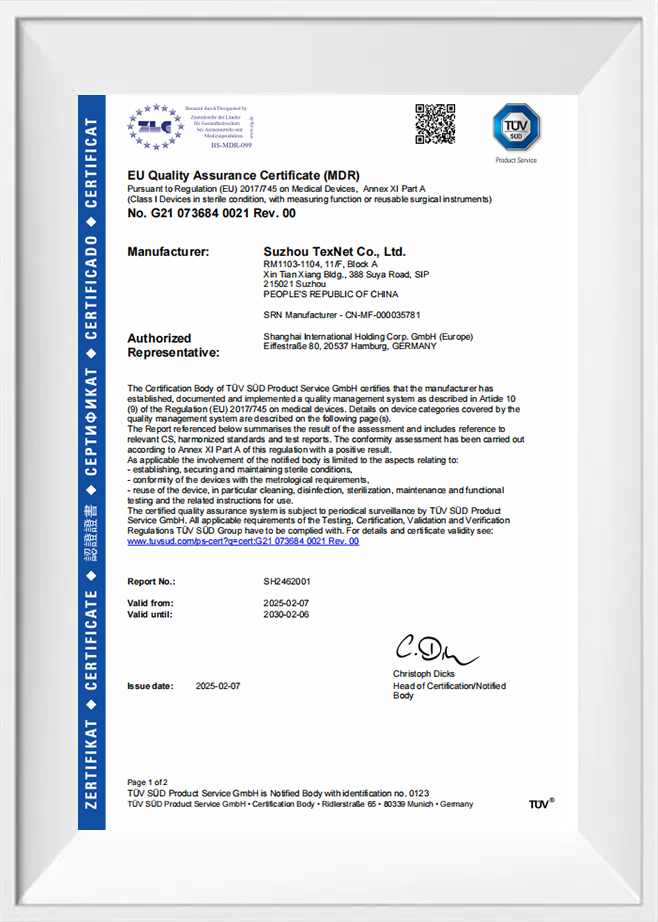

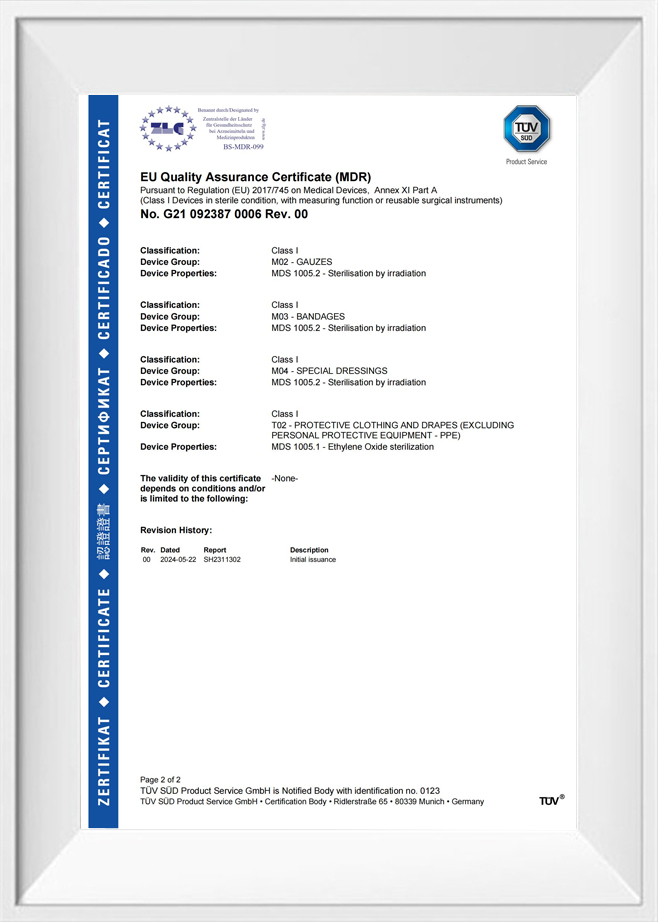

Interestingly, sterilization methods like gamma radiation or ethylene oxide can subtly impact absorbency by altering the moisture-handling properties of the fibers. Manufacturers must strike a careful balance between ensuring sterility and maintaining the physical integrity of the gauze. As a manufacturer with years of experience in textile engineering and medical compliance, we take these details seriously to ensure our gauze rolls meet rigorous international standards without compromising functionality.

For end-users, especially those responsible for bulk purchasing or clinical stocking, these absorbency characteristics are not just technical specs—they affect outcomes. A highly absorbent gauze bandage can minimize dressing changes, reduce the risk of infection, and ultimately save time and cost over the treatment cycle. When choosing gauze, it's important to move beyond general descriptors and assess actual performance metrics relevant to your care setting.

Whether you are managing an operating room or building a private-label wound care brand, selecting the right gauze rolls isn’t just about quantity—it’s about quality that performs under pressure. Our product range is designed with these real-world demands in mind, offering solutions that combine professional-grade absorbency with ease of use and reliability.

English

English Français

Français Español

Español Português

Português عربى

عربى